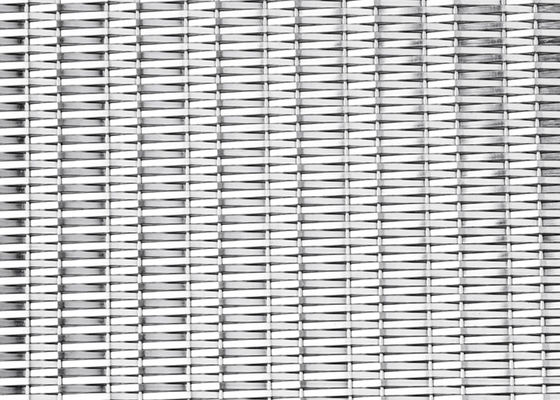

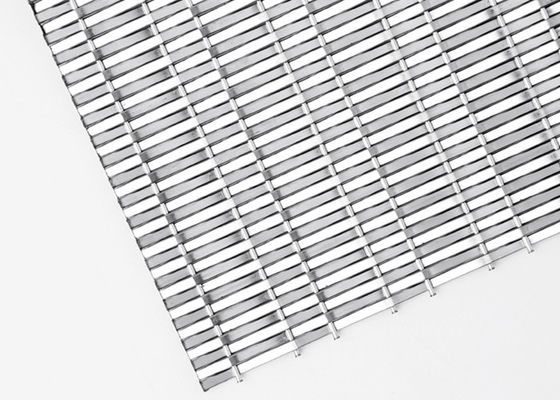

Stainless Steel Rigid Woven Wire Mesh Panels For Elevator Cladding

Woven Wire Mesh Panels Information:

Woven wire mesh panels is woven with high-quality aluminum alloy wire, copper wire, stainless steel wire, etc. the finished product can be the original color of metal, or spray into other colors such as bronze, ebony black and jujube red. The width and height can be determined at will. The product has the characteristics of solemnity, generosity and good three-dimensional effect. It is more attractive under the light. It is an ideal decorative material for modern hotels, restaurants, exhibition halls and so on.

Woven wire mesh panels belongs to green environmental protection construction and decoration materials. It can be used for a variety of purposes, with fast installation and long service life. It can be used for 10000 curtain walls, stair facades, etc.

Woven Wire Mesh Panels Data Sheet:

| Name |

Woven Wire Mesh Panels |

Material |

Stainless Steel |

| Surface |

Free oil |

Certificate |

ISO9000, SGS, ect |

|

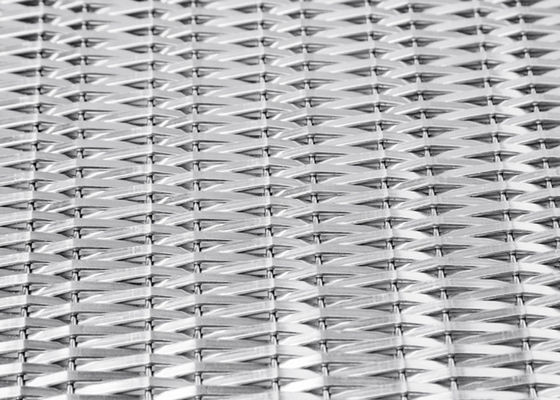

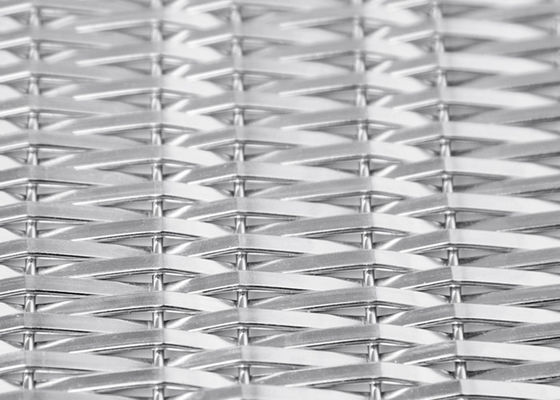

Weaving type

|

Plain Woven

|

Application |

Wall Coverings |

| Color |

Natural Color |

Packing |

Pallet, Wooden Case |

| Max Length |

3m |

Max Width |

1.5m |

Woven Wire Mesh Panels Selling Points:

1. Fireproof

2. Resistance to Corrosion

3. Durability

4. Environmentally Friendly

5. Easy to Clean

Woven Wire Mesh Panels Application:

► Railing

► Parking garages

► Fences enclosures

► Millwork cladding

► Ceilings canopies

► Space dividers

► Art signage

► Furniture

► Lighting

Woven Wire Mesh Panels Technology:

Individual lengths of wires are sent through a crimper to establish both warp wires (Long wires) and fill wires (Cross wires). The warp wires are individually positioned through the loom’s heddle frames. The heddle frames provide the movement that creates the “Shed” in which a cross wire will be inserted manually or automatically. Once the cross wire is in position, the loom’s sleigh will force it into the next available crimp pocket on the warp wires. Then, the heddle frames will reposition creating the “Over/Under” sequence.

FAQ:

Q1.What is architectural mesh?

Produced from 80% recycled material, our wire mesh can be designed to fit virtually any architectural structure, inside or out. Because of the strength and aesthetic appeal of our stainless steel architectural mesh, it offers new and versatile fields of application in architecture.

Q2. What about the lead time?

A:We often ship in a few days from stock. Custom orders can normally be supplier in 1-2 weeks.

Q3. Do you have any MOQ limit for product order?

A: Low MOQ, 5 square meter for sample checking is available

Q4. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive. Airline and sea shipping also optional.

Q5. How can get a specific quotation from us?

A: 1. let us know your requirements or application.

2. let us know the size(length & width) and quantity you need?

3. Please inform us of your company' name, address, Phone number and Email.

4.Please inform us of the shipping need by air or sea.

We quote according to your requirements or our suggestions.

Q6. How you would like to take payment?

A: 1.via Alibaba Trade insurance orders

2.We issue an invoice to pay our bank account.

Q7. PAYMENT

1. T/T 100% in advance. (Direct delivery, fast delivery)

2. T/T 30% as deposit, other 70% balance before shipment.(Need to wait until the final payment arrives, about 5 days will be delayed.

Woven Wire Mesh Panels Package:

Each pcs packing by paper, 1-50pcs in a wooden box.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!