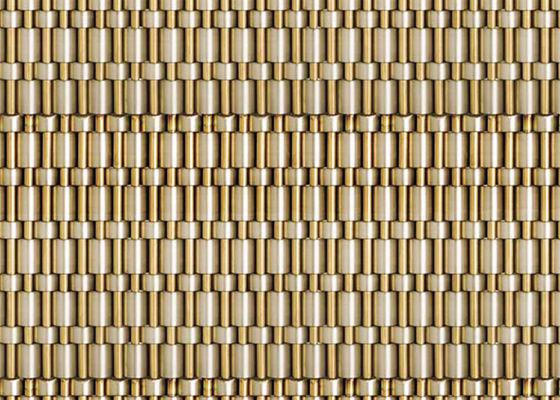

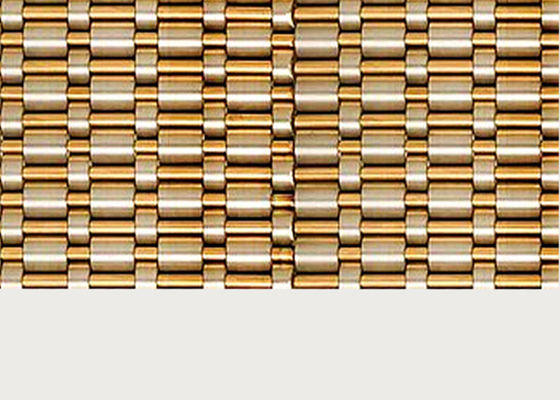

0% Opening Copper Wire Decorative Architectural Metal Mesh Panel For Elevator Wall

Architectural Metal Mesh Introduction:

Architectural Metal Mesh have a wide range of applications. They can be used for facade, partition, ceiling, sunshade, balcony and corridor, column surface decoration, roller shutter, stair passage and interior decoration of hotels, offices, exhibition halls, stores, etc. The feature of stainless steel decorative net is that it is not limited by the size of space, easy to install, and equipped with light will produce a very mysterious effect, with a strong sense of modernity. It can be said that the structure is beautiful, firm and durable.

Architectural Metal Mesh Advantage:

In the building, the sense of permeability and aesthetics can effectively adjust the light and heat comfort, make the outer wall form effective ventilation and prevent the accumulation of hot air for a long time. It is a kind of material that can be used as light diffuse reflection facilities, shading facilities, safety protection, anti flying birds and mosquitoes, light transmission and ventilation.

► Fireproof

► Resistance to Corrosion

► Durability

► Environmentally Friendly

► Easy to Clean

Architectural Metal Mesh data sheet:

| Material |

Stainless Steel |

Production Process |

Woven |

| Application |

Cladding, Dividers |

Color |

Bronze, Antique Brass |

| Certificate |

ISO, SGS |

Surface |

PVD, PVDF, Antique Brass |

| Max Size |

1.5m x 3.0m |

Packing |

Wooden case, pallet |

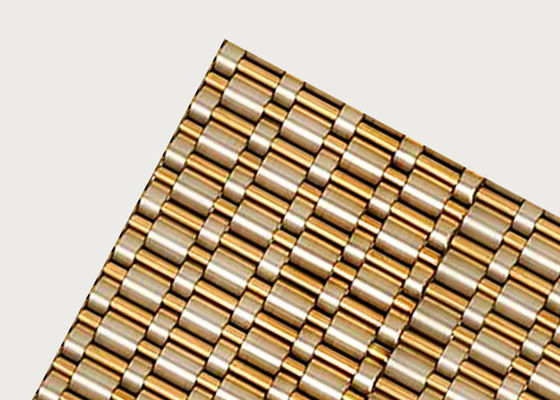

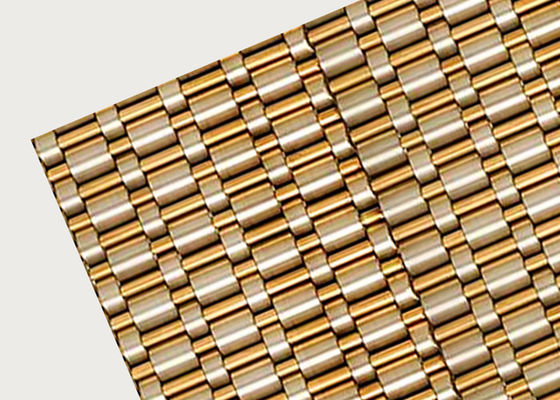

Architectural Metal Mesh Technique:

Individual lengths of wires are sent through a crimper to establish both warp wires (Long wires) and fill wires (Cross wires). The warp wires are individually positioned through the loom’s heddle frames. The heddle frames provide the movement that creates the “Shed” in which a cross wire will be inserted manually or automatically. Once the cross wire is in position, the loom’s sleigh will force it into the next available crimp pocket on the warp wires. Then, the heddle frames will reposition creating the “Over/Under” sequence.

Architectural Metal Mesh Application:

1. Architectural Metal Mesh has no rust, beautiful color, gorgeous color, beautiful appearance, strong and durable, and quality combination. It is also the most used decoration material for interior decoration in recent years. It has excellent selectivity for different users, high-grade and simple The atmospheric style and good ventilation effect are the combination of modern science and art.

2. Architectural Metal Mesh has a wide range of applications, and can be used for building facades, partitions, suspended ceilings, sunshades, balconies and corridors, column surface decoration, staircase passages, and high-end interior and exterior decoration of hotels, offices, exhibition halls, shops, museums, etc.

As a manufacturer of wire mesh with nearly half a century history, SHUOLONG have enough capacity to control the quality for each order. And at the same time, we can own the direct cost for wire mesh products. We just do wire mesh, we are professional.

Packing:

1> Rolls, panels on demand.

2> Wooden case, pallet, ect.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!