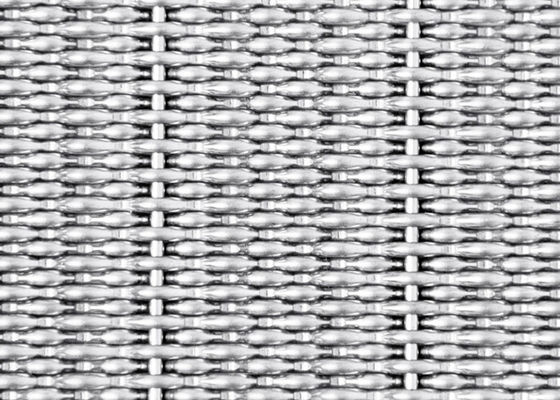

316L Stainless Steel Metal Fabric Partition For Woven Wire Mesh Panels

Woven Wire Mesh Panels Information:

Woven wire mesh panels has the advantages of incombustibility, high strength, firmness, easy maintenance, strong functionality, vivid and strong decorative effect, and can well protect building structures. There are many materials of metal decorative net, such as stainless steel, aluminum, copper, etc. Its installation is simple, fast, unique and elegant. Different light, different environment, different time period and different observation angle, its visual effect is very rich. It is applied to various occasions to highlight elegant temperament, extraordinary personality and noble taste.

Woven Wire Mesh Panels Data Sheet:

| Material |

Alu, SS304, SS316, Copper, ect |

Application |

Facade, Partitions, ect |

| Surface |

PVD, Paint, Antique Brass, ect |

Certificate |

ISO9000, SGS, ect |

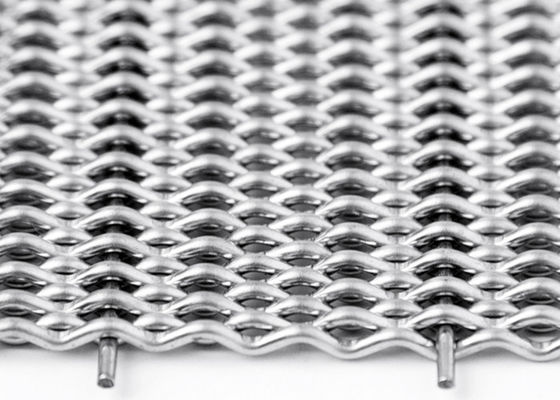

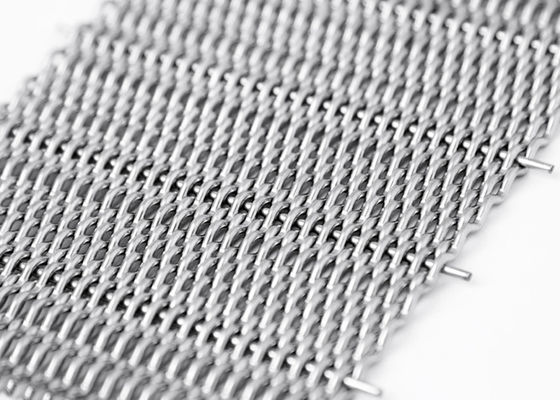

| Weaving type |

Plain Woven |

Size |

Can be customized |

| Packing |

Wooden Case, Pallet, ect |

Color |

Can be customized |

Woven Wire Mesh Panels Advantage:

1. Fireproof

2. Resistance to Corrosion

3. Durability

4. Environmentally Friendly

5. Easy to Clean

Woven Wire Mesh Panels Surface Treatment:

To enhance the appearance of the final product, we offer a variety of secondary finishes through our outside vendors. Typical secondary finishes applied to the wire mesh include PVD, Paint, Powder Coated, PVDF, Antique Brass, and so on.

Woven Wire Mesh Panels Theory:

Individual lengths of wires are sent through a crimper to establish both warp wires (Long wires) and fill wires (Cross wires). The warp wires are individually positioned through the loom’s heddle frames. The heddle frames provide the movement that creates the “Shed” in which a cross wire will be inserted manually or automatically. Once the cross wire is in position, the loom’s sleigh will force it into the next available crimp pocket on the warp wires. Then, the heddle frames will reposition creating the “Over/Under” sequence.

Woven Wire Mesh Panels Package:

Each pcs packing by paper, 1-50pcs in a wooden box.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!